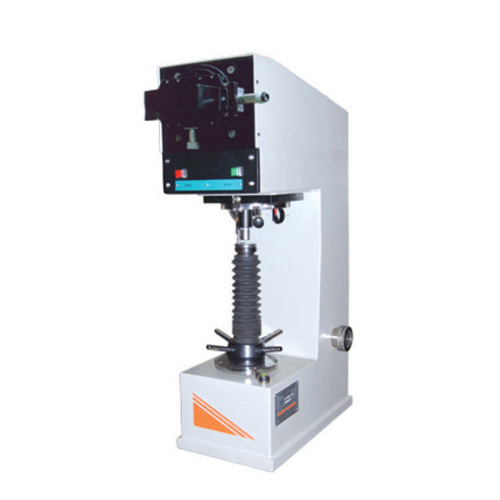

Vickers Hardness Tester

Price 165000 INR/ Piece

Vickers Hardness Tester Specification

- Product Type

- Manual

- Power

- 220 V, 50 Hz

- Weight

- 50 kg approx.

- Frequency

- 50 Hz

- Accuracy

- Complies with IS 1754, BS 427 (Part I), ASTM E-384

- Phase

- Single Phase

- Load Power

- 10 gm to 1 kg (Selectable)

- Gauge

- Included (Microscope)

- Features

- High accuracy, robust construction, easy operation, built-in microscope, precise loading mechanism

- Frame Type

- Portable Bench Model

- Stroke

- 10 mm

- Capacity

- Up to 1000g load

- Usage & Applications

- Measurement of hardness of metals, alloys, and ceramics using Vickers principle

- Display Type

- Analog Micrometer

- Color

- Off-White & Blue

- Voltage

- 220V AC

- Power Supply

- Electric

- Control Mode

- Push-Button/Lever Operated

- Dimension (L*W*H)

- 540 200 530 mm

- Automation Grade

- Manual

Vickers Hardness Tester Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Chennai

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 2 Week

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Nagaland, Uttarakhand, Daman and Diu, Lakshadweep, South India, East India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Kerala, Haryana, Uttar Pradesh, North India, Andhra Pradesh, Central India, Odisha, West India, Chhattisgarh, All India

About Vickers Hardness Tester

Our enterprise has extended its production in the market by offering superior quality Vickers Hardness Tester.

Product details

| Scale Least Count | 0.001mm |

| Material | Metal |

| Frequency | 50 Hz |

| Voltage | 220V |

| Optical magnification | 70 X |

| Max Test Height | 200 mm |

| Dimensions | L 585 x W 290 x H 860 |

| Depth of throat | 0.001mm |

Exceptional Accuracy & Reliable Results

The Vickers Hardness Tester stands out for its meticulous dead weight loading system and finely engineered Vickers diamond pyramid indenter, ensuring reliable, repeatable, and accurate hardness readings. Its compliance with internationally recognized standards such as IS 1754 and ASTM E-384 guarantees trustworthy performance for research, quality control, and industrial analysis purposes.

Ergonomic Design & Flexible Operation

Featuring a compact portable bench frame and powder-coated finish, the hardness tester is built to endure routine lab and shop-floor conditions. The easily accessible manual controls, analog micrometer display, and manual specimen stage ensure straightforward operation. A built-in LED/lamp provides clear illumination, while an optional CCD camera port is available for digital documentation.

Versatile Applications Across Materials

Designed for versatility, the Vickers Hardness Tester accommodates specimens up to 75 mm in height and measures a broad range of hardness values (HV 5 HV 1000). This makes it ideal for testing a wide array of metals, alloys, and ceramics in educational, industrial, and research institutions throughout India.

FAQs of Vickers Hardness Tester:

Q: How is a hardness test conducted using the Vickers Hardness Tester?

A: A specimen is placed on the manual cross travel stage, and an appropriate load (from 10g to 1kg) is applied via the dead weight system using the push-button or lever. The Vickers diamond pyramid indenter then creates an impression, which is measured through the built-in microscope (70X magnification) to determine the hardness value.Q: What materials can be tested with this Vickers Hardness Tester?

A: This tester is suitable for assessing the hardness of metals, alloys, and ceramics. Its wide measurement range (HV 5 HV 1000) and selectable load capacity make it ideal for diverse material types and hardness levels.Q: When should the Vickers Hardness Tester be used over other hardness methods?

A: The Vickers method is beneficial when precise hardness measurement and a small indentation are required, particularly for thin, brittle, or very hard materials where other methods like Brinell or Rockwell may not be appropriate.Q: Where can the Vickers Hardness Tester be installed and operated?

A: It is designed as a portable bench model suited for laboratories, research institutions, production quality control labs, and educational settings across India. Its compact size and robust construction allow flexible placement on various work surfaces.Q: What is the process for observing and recording the indentation measurement?

A: After indentation, users view the impression through the built-in microscope (10X eyepiece, 70X total magnification). The analog micrometer gauge facilitates precise measurement of the indentations diagonals, which are then used to calculate the Vickers Hardness value.Q: How does the built-in microscope and illumination benefit the testing procedure?

A: The integrated microscope, combined with bright LED/lamp illumination, ensures clear and accurate observation of the indentation. This supports consistent, error-free measurement and enhances usability during routine and detailed analyses.Q: What are the main advantages of using this Vickers Hardness Tester?

A: Key benefits include high accuracy, robust construction, ease of operation, precise loading mechanisms, compliance with multiple standards, and the option for digital imaging via a CCD camera port. Its manual controls and analog display offer control and simplicity for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compression Testing Machines Category

Hydraulic Press Hand Operated

Price 60000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 80 220 kg (varies by model)

Color : Blue/Gray (as per availability)

Usage & Applications : Bending, Pressing, Straightening, Assembling, Dismantling of various machine parts

CTM Hand Operated

Price 38000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 1015 kg

Color : BlueGrey

Usage & Applications : Sheet Metal Punching, Light Engineering Works

Power : Hand Operated

2000 kN Compression Machines

Price 120000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 300 Kilograms (kg)

Color : red

Usage & Applications : Pharmaceutical Analysis

Power : 230 Volt (v)

AIML Compression Testing Machine

Price 350000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 200 Kilograms (kg)

Color : blue

Usage & Applications : Pharmaceutical Analysis

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry